Gait analysis equipment is a valuable tool used in medicine, rehabilitation, sports science, and biomechanics research. By capturing motion data from walking or exercising, it enables precise analysis of gait patterns, joint angles, and mechanical parameters. With the rapid development of medical and sports rehabilitation, gait analysis equipment has become widely used in hospitals, rehabilitation centers, and research institutions.

However, to ensure optimal performance, a sound installation and commissioning process is crucial. The following details the complete operation process of gait analysis equipment, including equipment receipt, environmental preparation, installation and deployment, system commissioning, calibration testing, and routine maintenance.

The first step in equipment installation is equipment receipt and inspection. Upon arrival at the user site, a visual inspection should be performed immediately to ensure no damage occurred during transportation.

This inspection should include ensuring that all accessories, including the main unit, sensors, camera, force plate, marker sphere, cables, and auxiliary software, are present. Particular attention should be paid to inspecting vulnerable components, such as the camera lens, optical marker sphere, and force plate surface, for scratches or cracks. Furthermore, the equipment list and order should be verified to ensure that the model and functionality meet the purchase requirements. If any parts are missing or damaged, contact the supplier immediately to avoid impacting subsequent installation.

After confirming the equipment is intact, the next step is environmental preparation.

Gait analysis equipment has strict requirements for its installation environment, typically requiring a relatively spacious, well-lit experimental or training area. The space should ensure sufficient length and width for human walking or movement, while also allowing for equipment layout and access. The floor should be flat and solid to accommodate the force plate and other sensors, while also preventing vibration or movement during use.

The lighting environment should avoid strong reflections or direct light. Optical capture equipment, in particular, requires high uniformity and stability of ambient light. To prevent interference, the power outlet should be stable and, if possible, use an independent power supply circuit to prevent voltage fluctuations that may affect equipment performance. After completing environmental preparation, the work area should be demarcated, and the equipment placement and walking path should be marked to facilitate subsequent wiring and device mounting.

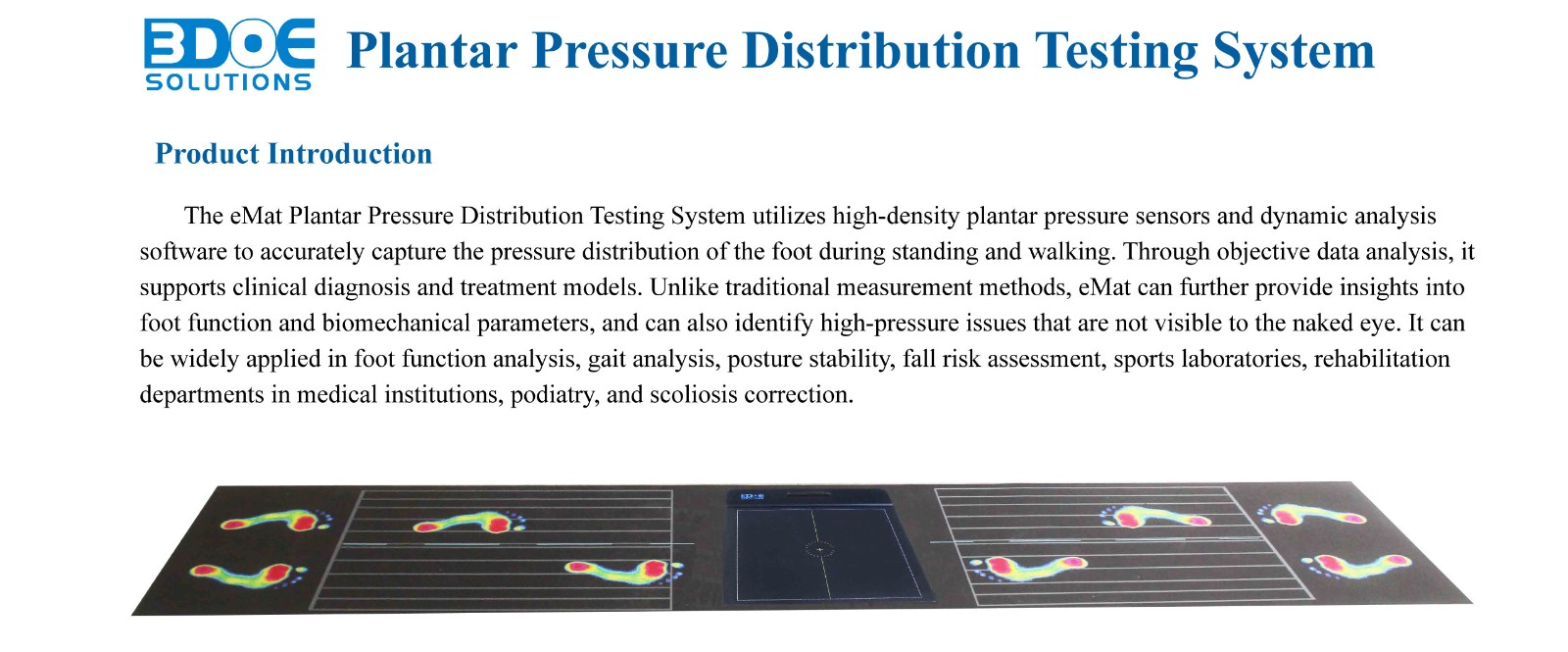

Plant Pressure Distribution System

The actual installation of the equipment involves hardware layout and mounting. When placing the sensors, first determine the precise positions of the camera, optical marker spheres, and force plate according to the manufacturer's installation manual. Cameras are typically mounted on both sides of the walking path and in front and behind to capture human movements from multiple angles.

The camera height should be adjusted according to the subject's height to ensure coverage of key joints and limb points. Optical markers or inertial sensors should be placed at key points on the subject's body, such as the ankle, knee, hip, and torso, according to the experimental plan. The force plate should be embedded in the ground or fixed to a bracket, ensuring that the surface is flush with the ground to ensure accurate force measurement. During cabling, cables should avoid crossing or pinching each other to ensure stable signal transmission. Protective measures should also be taken to prevent the subject from tripping or damaging the equipment.

After hardware installation is complete, the system debugging phase begins. This begins with device startup and software installation.

Following the manufacturer's instructions, connect the host computer to the sensors, camera, and force plate, and turn on the power. Launch the device's built-in software to perform a preliminary system identification to ensure that all hardware is correctly identified. If any disconnected or abnormal devices are detected, check the interfaces and cables and make corrections as prompted.

During software debugging, parameters such as sampling frequency, capture mode, and force plate calibration mode need to be configured according to the experimental requirements. During this phase, the camera's focus, exposure, and viewing angle should also be adjusted to ensure clear capture and unobstructed key points. For multi-camera systems, synchronization settings are also required to ensure strict temporal consistency of data from different viewpoints.

After system debugging is complete, calibration and verification are key steps. Gait analysis equipment typically offers various calibration methods, including calibration with a calibration plate, gait calibration, or body landmark calibration. By capturing images on a calibration plate of known dimensions, the spatial relationship between cameras and the accuracy of 3D reconstruction can be determined.

Force plate calibration requires applying a known weight to confirm force measurement accuracy. Landmark calibration involves placing marker spheres at key joints or skeletal locations on the subject and conducting a motion capture test run to ensure the accuracy of data such as joint angles, stride length, and cadence. After calibration, verification should be conducted through a small walking or exercise test to observe data stability and repeatability. If significant deviations are observed, the camera position should be readjusted or the sensor recalibrated.

After equipment debugging is completed and accuracy verified, routine usage protocols and maintenance procedures should be established. Equipment operators should be familiar with the software interface, data collection process, and emergency troubleshooting procedures.

Equipment hardware should undergo regular inspections, including camera lens cleanliness, cable securement, force plate surface flatness, and sensor battery charge. Software updates and data backups should be timely to ensure data security and functionality.

In addition, subject management protocols should be established to ensure safety during experiments, avoid damage to equipment, and ensure comparable and scientific data.

+86-0755-86131192

+86-0755-86131192 2025-08-13

2025-08-13 Back to list

Back to list

+86-0755-86131192

+86-0755-86131192